Crop storage humidification & humidity control

When crops, particularly salad vegetables, are harvested in the summer months, the crops are at whatever temperature pertains on that day. For the crop to reach the customer it has to be kept fresh and, in order to do this, the crop is cooled very rapidly to between 2 and 4°C. If the crop has been harvested at >20°C, the degree of cooling required to bring the crop to storage temperature will damage the crop.

To counter this, moisture is added during the chill down period. However it is not possible to humidify during the whole chilling period as the duty requirement would be so high that it is not commercially viable.

The humidification is therefore timed to operate when the cooling is off, to give a fog in the store so that the crop can reabsorb moisture from the air and also to provide residual moisture to prevent moisture loss from the crop during the next chill cycle.

The normal cycle is 15 minutes of cooling followed by 5 minutes of fogging, this cycle being repeated until the crop is down to temperature. There is no humidity control for this process and control is achieved by using a timing circuit in the plant control panel that runs the humidifier. It is critical that the fans from the chiller plant run all the time during this process so that the air distribution paths are maintained.

Benefits of Condair humidification in crop storage include:

- Improved productivity through reduced product weight loss

- Extended potential storage duration and longer shelf life

- Extensive expertise around the world in many agricultural applications

- Comprehensive product range to precisely meet customers' requirements

- Low energy systems to reduce operating costs and improve humidity control

- Comprehensive service of advice, design, supply, installation, commissioning, maintenance and spares supply

Other industries where Condair delivers vital humidity control

Insectary & insect breeding

Breeding of insects for zoology, research or to contribute protein to the food chain, requires specialist humidity control s...

Read moreOther humidifier applications

Humidification and evaporative cooling is employed in many other applications around the world.

Read moreHuman Health & Comfort

Preventing illness and improving health in many situations of our daily lives.

Read moreHumidification in food & beverage manufacturing

Humidity control can enhance productivity in food & beverage manufacturing to improve product quality and reduce waste.

Read moreHumidification in industrial & commercial manufacturing

Optimal humidity control can improve productivity in many industrial and commercial manufacturing processes.

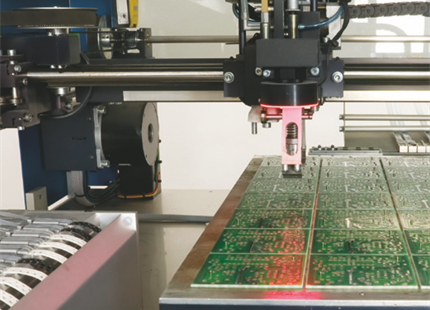

Read moreElectronics manufacturing

Eliminate harmful electrostatic discharge with humidification.

Read moreSpray booth humidification

Prevents evaporation of water-based paints and improves finish.

Read moreMuseums, galleries, art & antiques humidification

Preservation of works of art & antiques & fittings and features.

Read moreConcert halls & organs humidification

Preserving organs & protecting wooden instruments & auditoriums.

Read moreData centre humidification

Provides high capacity, low cost evaporative cooling and combats ESD.

Read more